“Knowledge is power”

People often forget how complex it is to make a piece of clothing, let alone a meter of fabric. There are countless production steps that have been taken before you can even buy your favourite T-shirt, bra or legging. At Liebaert it all starts with the raw materials such as Elastane, Nylon and Polyester. These raw materials are then knitted and woven into fabrics and narrows in our knitting and weaving department which is the heart of Liebaert’s technology and know how.

Every year we make around 300 new fabrics and many of the machines we have in production were designed specifically for our company. Our integrated dye house and fully automated color kitchen allows us to develop over 5000 colors every year. Together with our own printing and garment making factory this makes us a real one stop shop in the heart of Europe. With a permanent monitoring of every step of the production we are able to guarantee a ‘best in class’ quality that is consistent and lasting.

KNITTED FABRICS

YARNS

The quality of our products is not only determined by our production process but also by the quality of the fibres we use. For this reason we only buy from the best European suppliers. At Liebaert we work with different types of fibres ranging from man-made fibres such as Polyamide, Polyester en Elastane to natural fibres such as Rubber, Cotton and Modal to more technical fibres such as stainless steel, copper and Teflon.

WARP & CIRCULAR KNITTING

At Liebaert we produce both circular and warp knitted fabrics. Thanks to a high diversity of machines we are able to provide our customers with a very broad product range.

SOLVENT SCOURING

Before starting the dyeing process all of our fabrics are washed in our solvent scouring machine. During this process we wash out the spinning oils and relax the fabric in order to guarantee a good dyeing quality.

THERMO FIXATION

During this process the fabric is heated up at around 195 degrees celsius. By doing this we give the fabric dimensional stability and we make sure it has the right weight and elasticity.

DYEING

Every year we produce up to 5000 new colours. Needless to say that this is one of the most important processes in our factory.

FINISHING

After dyeing the fabrics are dried at around 130 degrees. During this process we also add special finishes.

PRINTING

At Liebaert we have 2 printing departments. One that is specialised in digital printing and another in traditional rotary printing.

INSPECTION

Quality is the most important thing in our company. Therefore, every meter is inspected electronically and visually to make sure our customers get only first grade quality goods.

TRANSPORTATION

Our products are delivered all across the globe.

NARROW ELASTICS

YARNS

The quality of our products is not only determined by our production process but also by the quality of the fibres we use. For this reason we only buy from the best European suppliers. At Liebaert we work with different types of fibres ranging from man-made fibres such as Polyamide, Polyester en Elastane to natural fibres such as Rubber, Cotton and Modal to more technical fibres such as stainless steel, copper and Teflon.

COVERING

During the covering process we cover elastane yarns with polyester or polyamide yarns. By doing this we are able to create nicely balanced narrows.

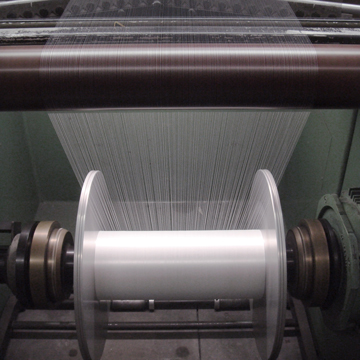

WARPING

During the warping process we put individual yarns onto a beam.

WEAVING & KNITTING

At Liebaert we produce both woven and knitted narrow elastics. We are able to produce anything from very fine elastics for intimates to very strong and wide elastics for technical applications.

DYEING

Our narrows are dyed during a continuous dyeing process. It also allows us to add special finishes.

SILICONING

We are able to apply different types of silicone in various shapes on all our products. This process is typically used for medical applications and for anti-slip purposes.

INSPECTION

Quality is of the utmost importance for our company. Therefore, every meter is inspected electronically and visually to make sure our customers get first grade quality.

TRANSPORTATION

Our products are delivered all across the globe.